Estimated reading time: 7 minutes

Traceability will become a reality in the near future, and the RMIS is urging producers to start getting on board. The document outlines the procedure to obtain your Global Location Number (GLN), which is a once-off for each of your production units, and is a free service provided by the RMIS.

Please visit the RMIS website and get your GLN at https://productionunit.rmis.co.za/

Traceability Data Exchange Platform

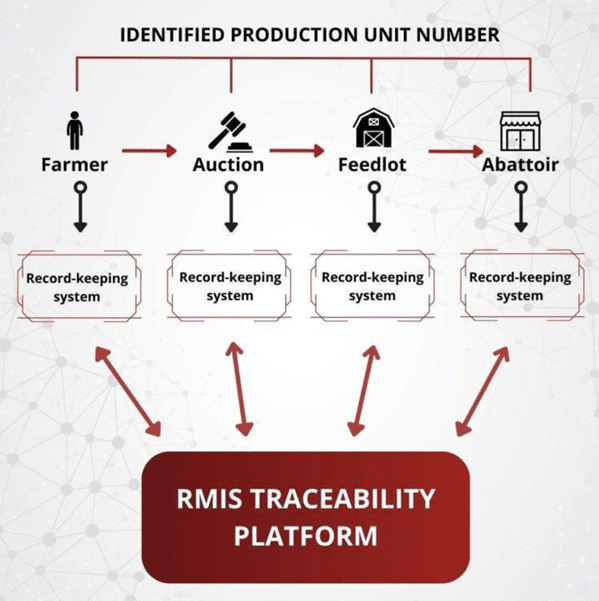

This is a traceability data exchange platform for the South African red meat value chain, that is driven by the red meat industry and aligned with the government to assist with national disease management, market access requirements, and meat safety. The platform focuses on identifying, capturing, and efficiently exchanging relevant traceability data in a standardised language between role players.

The traceability platform has been named ‘Red Meat and Livestock Identification and Traceability – South Africa’. Guidance regarding the platform and relevant information, as well as implementation is guided by a traceability task team, established on 3 October 2024, comprising key representatives from industry organisations, including RPO, NALFA-SA, SA Red MeatSA (Red Meat has since decided to withdraw from the task team), the National Department of Agriculture, Cape Wools & NWGA, RMIS, Gendac, and GS1. RMIS is also in continuous consultation with other relevant role-players including auctioneers, SAFA and RMAA.

Platform Development Phases

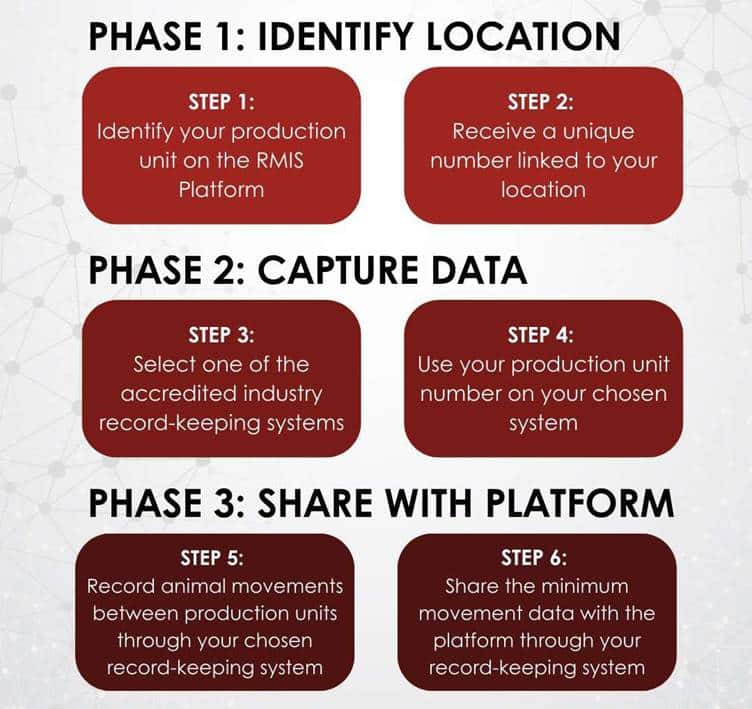

A phased approach will enhance resource focus and efficiency to ensure accurate results in the shortest period possible. The image below points out the three phases and the steps each consists of:

Phase 1: Identify locations by issuing Production Unit Numbers (GLNs – Global Location Numbers)

RMIS launched Phase 1 on 1 November 2024 which focuses on the identification and numbering of all key locations within the red meat value chain. Each site, including communal land farms, commercial farms, auction houses, feedlots, meat processing facilities, testing stations, and abattoirs will receive a unique production unit number, also known as a Global Location Number (GLN).

GLNs are unique identifiers in the GS1 standard, assigned to physical locations within a supply chain. Within the traceability context, assigning unique GLNs to relevant locations within the red meat industry supply chain, will ensure communication and accurate referencing. GS1, through its global standards, ensures national and international credibility, while maintaining alignment with the primary value chain, retail, and export sectors.

Registered production unit numbers form the foundation of the Traceability Platform.

Role-players can already register their production units by visiting: https://productionunit.rmis.co.za/

A video explaining traceability and its development phases can be viewed and shared at https://rmis.co.za/services/traceability/. This website also provides access to the platform to register Production Units, along with a step-by-step video guide. Additionally, registered Production Units are displayed on an interactive map at https://rmis.co.za/rmis-traceability- platform/, allowing users to verify the legitimacy and location of a Production Unit Number.

This phase is ongoing and will continue indefinitely as long as new production units continue to register. During phase 2, as various record-keeping systems integrate with the platform, this number will serve as a key location reference for sharing traceability data.

Phase 2: Capture relevant animal data through recordkeeping systems that can be shared to enable traceability.

The platform is designed to be widely accessible, ensuring that the entire industry can participate in this initiative. To achieve this, the platform integrates with existing record-keeping systems, allowing seamless data exchange. This approach enables role players to continue using their current record-keeping systems – provided these record-keeping systems can integrate with the traceability platform — rather than being required to adopt a single, uniform system. Data is thus decentralised, which enhances trust and participation.

Requirements for record-keeping system integration

For record-keeping systems to integrate, the following minimum requirements must be digitally recorded:

- Production unit number (GLN)

- GPS coordinates of animals’ location

- Date stamp of the scanned animal

- Tag IDs (individually identifying each animal)

- Livestock species

- Livestock quantities (when moved) and be able to integrate through a secure HTTP API provided by the platform.

Record-keeping systems throughout the value chain can apply to be integrated into the platform to exchange traceability data. The application form is available at https://rmis.co.za/services/traceability/

As this is a phased approach, current tags and their numbers used in the industry will be able to integrate into the platform through accredited record-keeping systems. Initially, all technologies will be accommodated to prevent duplication and minimise additional costs for producers. These technologies also cater to diverse producer needs, offering different functionalities. Hardware should comply with international identification standards such as ICAR, PASS 44, PASS 66, and similar approved regulations of which standards can and will be explored.

To ensure that numbers are issued consistently and without duplication, a centralised tag numbering system, managed by RMIS, is being negotiated that will be issuing numbers to independent record-keeping systems and tag manufacturers. A centralised number bank enhances the credibility and recognition of tag numbers in the comprehensive traceability platform and prevents number duplication. The numbering system under consideration, is also supplied by GS1. These unique numbers have a maximum of 15 digits and can be accommodated by all tag technologies. This will provide a structure for national animal number management, while being recognised by retail and global. Once the issuing of centralised numbers is in place, a method will be established for uploading the existing numbers of animals from accredited bodies such as ICAR.

Collaboration with record-keeping systems has already been initiated, with communications sent out and exploratory meetings conducted. The following record-keeping systems will be participating in the integration with the platform and have indicated their ability to comply with the requirements (but are not limited to):

- Allflex Connect Software

- ID-Scan Software

- Datamars Livestock Software

- Gigalot Software

- AIMS Software

- Sparta Software

- Logix Software

- Karan Software

- FlexiAuction Software

- Matrix Software

- Gallagher Software

- GMP Software

- Herdmaster Software

The API development and integration are already in progress with a few record-keeping systems to establish POC. After the POC, the API integration will be rolled out to all accredited record-keeping systems.

Phase 3: Share the necessary data in a standardized format to enable traceability.

The fundamental principle of phase 3, is that data will be decentralised within different record-keeping systems and shared in a standardised way to create the movement path of livestock through the value chain on the Traceability Platform.

The minimal traceability data exchanged through record-keeping systems on the platform, as animals move, will include:

- Production unit number

- GPS location

- Animal identification

- Date

Timeline:

| Task | Milestone | Status |

| Phase 1: Application to register production unit number. | November 2024 | Completed |

| Phase 2a: Deployment of a workable proof of concept. | May 2025 | In progress |

| Phase 2b: Integration of record-keeping systems. | November 2025 | In progress |

| Phase 3: Animal movement data exchange. | November 2025 | Pipeline |

The Traceability Platform is already in development, parallel with the API integration of the record-keeping systems. The security of the shared traceability data was thoroughly investigated to be developed to ensure data security. The reporting and integration of traceability data will also be finalised in this stage, ensuring accurate, quick and user-friendly reports.

The roadmap and puzzle pieces to reach the end goal of livestock traceability are realistically achievable. Still, it requires a collaborative attempt by all industry role players, including small-scale farmers, commercial farmers, auction houses, feedlots, abattoirs, service providers, product providers, organised agricultural organisations, and the government.

By leveraging the RMIS-tailored production unit (GLN) onboarding spatial registration application, participants can seamlessly register onto the platform while maintaining the integrity and accuracy of their data. This collaborative effort enhances the visibility of locations of the role players throughout the red meat value chain. Moving forward, the implementation of this traceability network will undoubtedly contribute to the industry’s competitiveness, sustainability, and resilience in both local and global markets. – RMIS