Estimated reading time: 6 minutes

When you decide to store grain on your farm and need a storage structure for this purpose, there is most certainly no room for error. It is one thing to have a well-thought-out plan, but it is usually also an expensive plan. So, to prevent costly losses, it is wise to make use of expert advice from the outset.

The manual Structures and Equipment for the Storage and Handling of Grain on the Farm, published by the ARC-Agricultural Engineering, contains guidelines and important information that should be kept in mind once a producer decides to erect his or her own grain storage structure.

First of all, you need to determine what the main purpose of storing grain on your farm is. Grain can be stored for own use, which means it is likely to be stored for a reasonably long period, or it can serve as buffer (temporary) storage until it can be delivered to the depot at a more convenient time or until prices are more favourable.

Factors that influence planning

- The distance between the point of harvest and the storage point requires thorough planning, as it can have an impact on the harvest rate and machinery utilisation. It may be worthwhile to consider using an existing structure on the farm as is or converting it to a suitable grain storage structure.

- It is essential to determine what the product requirements are. Does it require drying or aeration, insect control or specific handling?

- Is the available site suitable for the intended purpose? Is it accessible? Is there room to work and move around? What do further possibilities in terms of construction, extensions or power supply look like?

- What requirements are there regarding safe and efficient usage of handling equipment, accessibility for repair purposes and cost-effectiveness?

- One of the most important factors is the type of structure you want to use. Unlike water, which has a horizontal surface, a pile of grain has the form of a cone. The grain will therefore put additional stresses and strains on the structure. Is the design structurally strong enough and can the necessary building practices be applied during erection or conversion?

Types of structures for grain storage

There are mainly three types of structures, namely existing shed-type structures, temporary structures and silos.

Existing structures for grain storage

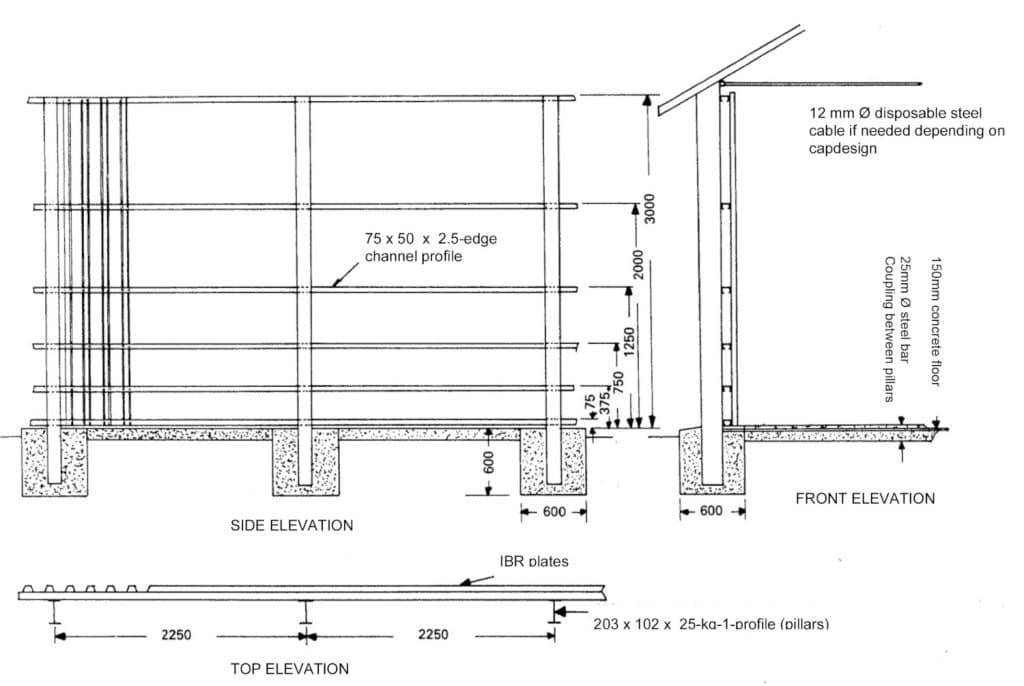

It is sometimes possible to convert existing sheds for buffer or temporary storage. However, in such cases grain handling tends to be more difficult than in purpose-designed structures. The most general structure is the horizontal shed with or without sidewalls or doors.

To convert this structure into an effective grain storage structure, additional vertical pillars and horizontal reinforcing beams are necessary between the pillars. The bottom part of the walls must be able to withstand a greater outward pressure than the top part when the shed is filled with grain. In addition, the top and bottom ends of the pillars on the opposite sides of the structure should be connected for additional strength to withstand outward pressure.

Because the grain exerts outward pressure, the wall cover must be attached to the inside of the pillars and the horizontal reinforcing beams. Corrugated galvanised IBR steel sheets can be used for this purpose.

The floor should be a hard, smooth concrete slab that facilitates easy cleaning. Underneath this concrete floor, a layer of sand with a plastic cover is necessary to keep moisture out.

Temporary storage

This can be a commercially available silo bag or else temporary storage can be erected. Moveable, welded mesh wire silos are suitable for this purpose. They are quick and easy to erect and can be dismantled and erected again when necessary.

The only disadvantage of this type of grain storage is that the capacity of this kind of container is limited to the strength of the wire mesh.

It is erected in a cylindrical shape, like a corrugated iron dam, and lined on the inside of the wall and on the floor with plastic sheeting. A watertight brick-layered floor, described in the manual, which isolates the grain from the soil and is strong enough to bear the weight of the grain is also required.

For example, a silo with a diameter of 4,5m and a height of two metres has a capacity of around 24 tons of wheat. For a silo this size a 75mm mesh with a wire diameter of 3,5mm is used. The capacity can be doubled if two of these cylinders are placed on top of each other. However, the diameter of the bottom cylinder must then be 4mm in order to withstand the increased pressure due to the greater grain depth.

It is important to allow an overlap of at least 150mm where the two ends of the cylinder meet. These ends must be clamped together thoroughly to withstand the tension in the wire when the silo is filled with grain.

This silo should be filled and emptied from the centre of the cylinder, in order to prevent extreme stress fractures from developing in the walls of the cylinder.

Erecting a steel and brick silo

A well-planned silo can be used for many years if it is erected according to the correct specifications and regulations.

Cylindrical silos are cheaper and stronger than rectangular or square storage constructions. The silo walls are formed with a double layer of bricks, plastered on the inside and the outside, and contains steel reinforcements. The position of a constructed silo is also vital.

Apart from the normal aspects relating to the erection of a grain storage container, the following must be kept in mind:

- The level of the groundwater table where a service pit or conical floor is planned.

- Solid soil formation for a good foundation and silo floors.

- Drainage of rainwater.

Other important factors that should be considered when any type of grain storage structure is erected include the aeration of grain, grain-handling equipment, grain drying, filling and emptying of silos, and energy requirements.

For more information, email Fanie Vorster at vorsters@arc.agric.za. To order the complete manual on Structures and Equipment for the Storage and Handling of Grain on the Farm, email Elmarie Stoltz at stoltze@arc.agric.za. – Koos du Pisanie and Fanie Vorster (PrEng), ARC-Agricultural Engineering