Estimated reading time: 7 minutes

Number Two Piggeries, also known as N2P, has come a long way since its humble beginning as a pig breeding unit founded in Queenstown in 1976 by David Osborne and David Miles. The company has since transformed itself from a small-scale farming venture into a notable market leader in South Africa’s pork production industry.

Today, N2P is an agricultural holding company that focusses on primary production and processing within the pork industry. They have four abattoirs and 26 biosecure piggeries ranging from weaner and grower farms, to full farrow-to-finish units across South Africa and Namibia. N2P also has an interest in the Pig Improvement Company (PIC) South Africa.

With an impressive market share of 23 to 24% based on the national sow herd and slaughter volumes, Stockfarm wanted to know more about the N2P business model and what gives them the leading edge in a highly competitive industry.

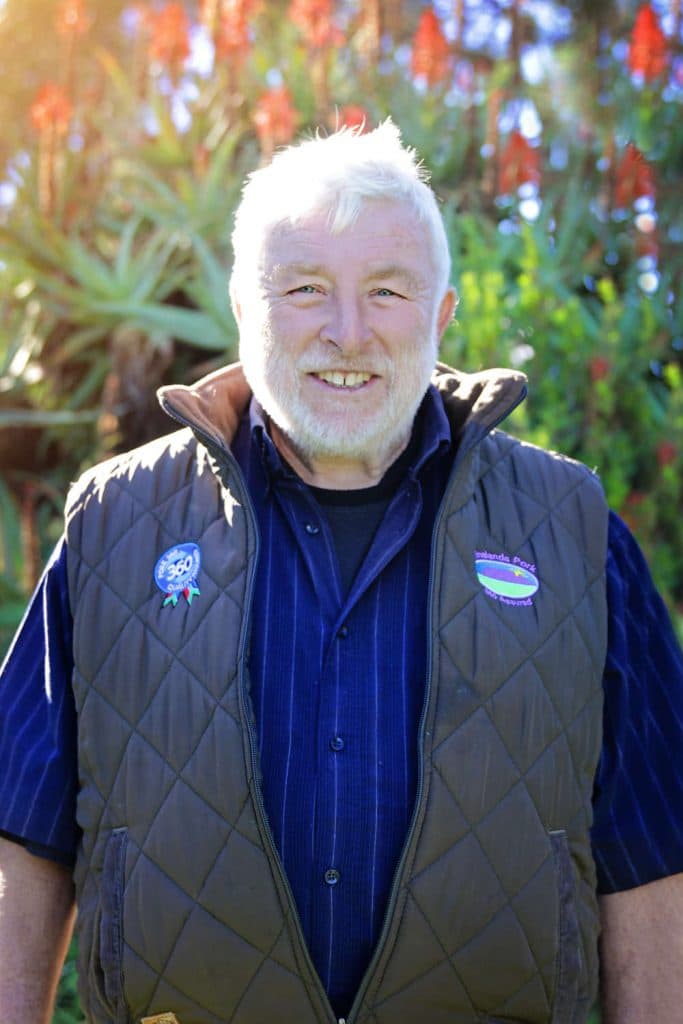

David Osborne still heads the company while David Miles has in the meanwhile retired, but is still involved in N2P as a shareholder. The rest of the team consists of Jeff van Zyl, a highly experienced pig farmer and head of large herds, and Philip von Memerty, N2P shareholder and head of piggeries. Mark Schulpfort was an operating partner until 2015 when he took early retirement.

A very challenging industry

Philip joined N2P in 1980 and summarises his journey with the company as “an adventure with many highs and lows” in an industry that is certainly a challenging business.

Opportunities for growth were identified and in 1980, N2P expanded to Aliwal North and Golden Valley near Cookhouse. “At the time, some DairyBelle cheese factories were operating in the area and N2P took advantage of the opportunity to purchase some of the whey from the manufacturing plants,” says Philip.

The whey was fed in combination with balanced rations, giving them a competitive edge in terms of feed and total production cost. “The energy value of the liquid whey simply meant that we fed less expensive balanced rations per pig to the point of sale.”

David Osborne identified the need for N2P to expand into the South African pig production sector without necessarily growing the national pig herd. “Capital was a limiting factor, but the appetite to grow and the relationship built with auctioneers and agents, afforded Dave and N2P opportunities to form joint ventures with existing pig farmers,” says Philip.

In 1994, their growth outside of the Eastern Cape gained momentum when N2P started new ventures in KwaZulu-Natal and the Western Cape.

The cornerstones of success

Their success, emphasises Philip, is all about being custodians of the environment, focussing on attention to detail by sticking to the basics of good animal husbandry, as well as treating people well. “Put simply, if integrity and honesty are non-negotiable and if we operate safely and with strong ethics, we will succeed.”

Value creation and measurement at N2P is founded on people, genetics, feed, housing and infrastructure linked with suppliers and markets.

Dedicated people

N2P has always relied on the dedication of people, strict financial disciplines and controls, strong leadership, quality of production, traceability standards and a strong support network of specialists such as bankers, genetics suppliers, veterinarians, feed millers, technical specialists, nutritionists and the like. For example, they have a very good relationship with a company such as Lionel’s Veterinary Supplies.

“The focus has always been on people and the management of efficiencies,” says Philip. “Perseverance, hard work and determination, combined with a ‘buy in’ from management, allow all company role-players to embrace a disciplined vision of growth. Our challenge has always been to attract and retain good, honest stockmen who have an appetite for growth. Many of our top producers are those same youngsters who grew within our ranks.”

While the company has stringent policies, guidelines and controls in place, the management teams enjoy the freedom to delegate in their own style. This has had a major influence on the growth of the team, explains Philip.

“Each unit differs vastly from the next and the management teams are therefore allowed to manage their units so as to purposefully fit their conditions and circumstances,” he says. “I believe our success and growth have been because of teamwork. Thanks to collective teamwork right from the bottom up, we have made it happen.”

Role of genetics

PIC, a South African and international world leader in pig genetics, has an affiliation and close relationship with N2P, supplying them with world-class genetic material. PIC also has professional pig technicians available for on-farm support, with readily available international support also at their disposal.

Philip notes that they find PIC’s data collection and ability to perform benchmarking statistics to be quite a handy asset.

The feed regime

N2P uses balanced rations supplied by some of South Africa’s top milling companies. Some on-farm mixing is done using computerised liquid feeding farms. They also have a South African in-house nutritionist as well as a UK-based contact who ensure that they are constantly supplied with high-quality rations. These rations are regularly adjusted to suit raw material availability and pricing.

Housing and infrastructure

N2P regularly consults with local and international specialists regarding infrastructure design and equipment, which are adapted to South African conditions to give them the best possible advantage. “During the design phase we always put a lot of emphasis on pig welfare and biosecurity,” says Philip.

“Another important tool is the monitoring of all aspects of pig production and performance. For this, we had to draw up individual budgets for each operation, so that each unit can be evaluated individually. The aim was always to be competitive in terms of the cost involved in producing a kilogram of pork.”

Some of the parameters monitored in all N2P units on a weekly and monthly basis include:

- Feed conversion ratio (feed used to produce 1kg of pork sold).

- Number of pigs sold per sow per year.

- Percentage of females mated that farrowed.

- Interfarrowing period (days between weaning a sow and her being inseminated/served).

- Number of piglets born per sow farrowing.

- Number of piglets born alive or dead.

- Mortality percentage prior to weaning.

- Weaner mortality.

- Grower mortality.

- Weaning age and weight.

- Age and weight of slaughter pigs.

- Growth per day for growers and weaners.

Getting ahead

Improved management and superior genetics have led to improved levels of efficiencies. A decade ago, N2P was selling 21 to 24 pigs per sow per year. Currently a few herds are headed for 30 pigs sold per sow per year. A decade ago, feed conversion ratios varied from 3,40:1 to 3,85:1 across the units; today it varies from 3:1 to 3,4:1.

A final remark from Phillip: “Per capita pork consumption in South Africa is increasing. We must endeavour to continue to supply a safe, nutritious and delicious product that is also affordable. To do this, we have to build consumer trust and confidence in South African pork producers.” – Carin Venter, Stockfarm

For more information, visit Number Two Piggeries’ website at www.n2p.co.za.